Hallux Talon Xanthanase, is a patented enzyme breaker specifically developed to address the xanthan gums commonly utilized in drilling and fracturing fluids. The enzyme system attacks the xanthan-based drilling or fracturing fluid’s filter-cake damage by degrading the polymer that acts as a glue holding the bentonite or calcium carbonate together or dynamically formed filtercake on the formation faces and unbroken gel residue in the proppant pack. After effective degradation of the xanthan based damage, the soluble broken gel or bridging material can then be removed, ensuring even inflow into the wellbore.

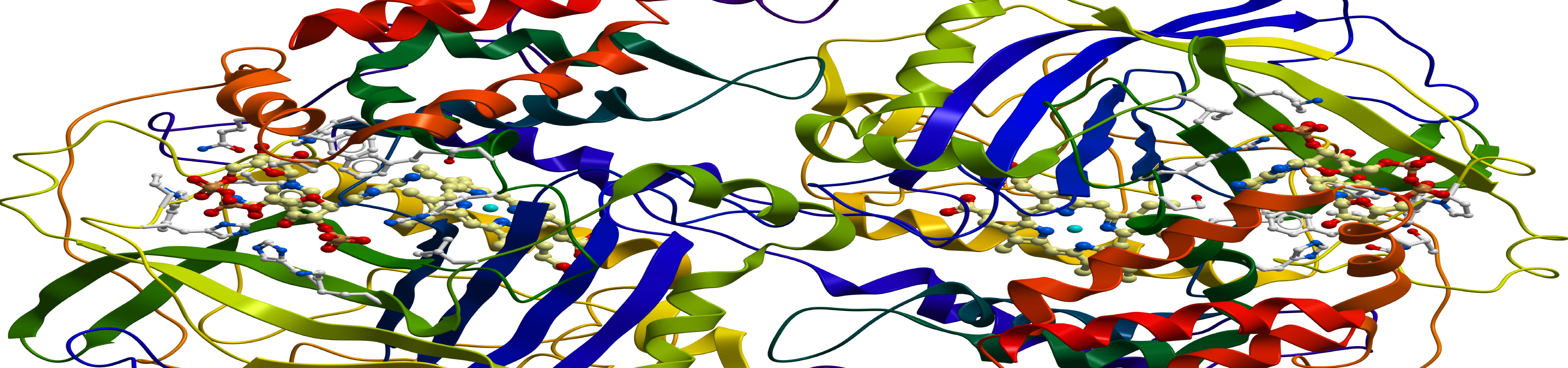

In order to accomplish effective structural dismantling of this highly complex xanthan polymer into manageable components the xanthan-specific enzymes would be specific to degrade or cleave either the α-1,2 or β-1,4 glycosidic linkages of the substituent and the β-1,4 glucosidic linkages of the backbone.

Extensive research combined with recent biotechnological advancements have led to the identification and isolation of fungal enzymes, which degrade xanthan polymers to non-damaging fragments. Additional fermentation and optimization provided for this xanthan-specific enzyme system to be utilized in damage removal treatments at temperatures ranging from 130°F to temperatures exceeding 250°F.

Features

Removes Filter Cake Damage

Removes filter cake damage created by drill-in fluids comprised of either starch, cellulose polymers, xanthan polymers, sized calcium carbonate or salt particulates.

Improves Fracture Conductivity

High Efficiency

Each of the enzymes utilized attack, or have an affinity toward, specific polymers in maximum degradation efficiency.

Customization

Polymer-specific enzymes allow each treatment to be customized for the specific type of polymeric damage.

Unique Chemistry

Enzymes do not undergo chemical or structural changes during the reactions they initiate and do not produce undesirable side reactions. They also possess an unique property called “turn-over” number. Typical “turn-over”numbers are in excess of one million which means that more than one million linkages of polymer substrate can be cleaved per minute. A great many more can be cleaved over the “life span” of the enzyme unit.

Temperature Stability

Stable at temperatures up to 250°F (121°C).

pH Stability

Effective in fluids that range in pH from 3 to 11. Recent advances in biotechnology have allowed for broader pH applications.

Non-Hazardous

Produced from all natural processes.

Compatibility

Compatible with all types of formations, base waters, tubular goods and proppants.

Benefits

Independent Laboratory Regained Permeability testing has shown that regained results can approach 100%.

Treatments are customized to the type of damage present, creating maximum cost and performance efficiency.

Applicable to a broad range of downhole temperatures.

Low and high pH stability of the enzymes allow for use in all fracturing fluids.

Environmentally friendly. Enzymes do not require any special handling or disposal.

Cost effective. High retained conductivity and high regained permeability have resulted in high productivity, which is a cost savings for the operator.

Effective as a remedial treatment to clean up inadequately broken frac fluids.

Noncorrosive to any metals which may be encountered in the well.

Safety Precautions

Although prolonged contact and breathing can produce an irritation in sensitized people, there are no special storage, handling, or environmental precautions necessary.

Competitive Products

None.

Let us customize a solution for your specific needs with one of our xanthanase products.