Applications

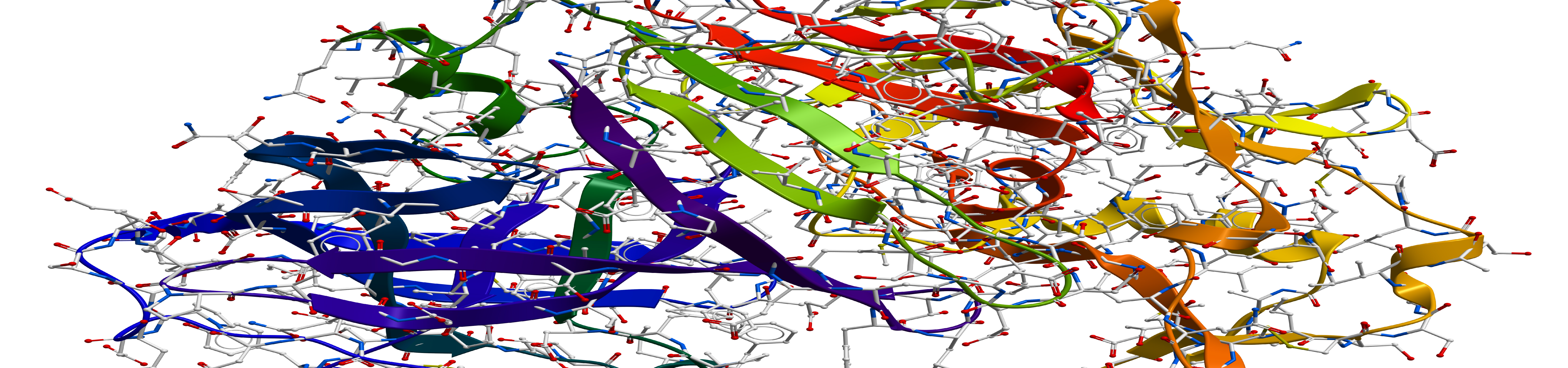

Hallux Talon Cellulase, is an enzyme breaker, custom-formulated to degrade cellulose polymer into non-damaging components at elevated temperatures.

Features

High Efficiency

Enzyme complex attacks, or has an affinity toward, specific polymer linkages resulting in mono-and di-saccharides, which maximizes degradation efficiency.

Customization

Polymer-specific enzymes are custom-designed for any cellulose or derivatized cellulose polymer.

Unique Chemistry

Enzymes do not undergo chemical or structural changes during the reactions they initiate and do not produce undesirable side reactions. They have a unique property called “turn-over” number. Typical “turn-over” numbers are in excess of one million which means that more than one million linkages of polymer substrate can be cleaved per minute. A great many more can be cleaved over the “life span” of the enzyme unit.

Temperature Stability

Stable at temperatures starting at 140°F (60°C) up to 250°F (121°C).

pH Stability

Effective in fluids that range in pH from 3 to 8.

Non-Hazardous

Produced from all natural processes.

Compatibility

Compatible with all types of formations, base waters, tubular goods and proppants (especially resin-coated proppants}, as well as a variety of surface-active agents.

Benefits

Proppant pack testing has shown that retained conductivities approaching 100% are possible.

Applicable to a broad range of downhole temperatures.

Low and high pH stability of the enzymes permit use in all fracturing fluids, workover operations and remedial treatments.

Environmentally friendly. Enzymes do not require any special handling or disposal.

Cost effective. High retained conductivity and high regained permeability result in high productivity, which is a cost savings for the operator.

Non-corrosive to any metals which may be encountered in the well.

Safety Precautions

Although prolonged contact and breathing can produce an irritation in sensitized people, there are no special storage, handling, toxicity or environmental precautions necessary.

Limitations

Suggested maximum temperature of 250°F (121°C).

Competitive Products

None.